Upgrading your F150’s lower control arm can enhance your truck’s performance. It’s a crucial component that affects handling and stability.

If you’re an F150 owner, you know the importance of a smooth ride. The lower control arm is key for this. It connects the wheel to the frame and allows for proper suspension movement. Over time, wear and tear can take a toll.

Upgrading to a new, high-quality lower control arm can make a big difference. It improves handling, reduces vibration, and ensures your truck runs smoothly. Whether you’re off-roading or driving on highways, this upgrade is worth considering. Stay tuned to learn why an F150 lower control arm upgrade can be a game-changer for your vehicle.

Introduction To F150 Lower Control Arm Upgrade

Upgrading the lower control arms of your F150 can greatly improve your truck’s performance. The control arm is an essential part of the suspension system. It connects the wheel hub to the frame. It helps with steering and stability. A quality upgrade can enhance your driving experience.

Benefits Of Upgrading

There are several benefits to upgrading your F150’s lower control arms:

- Improved Handling: Better control on rough terrains.

- Increased Durability: High-quality materials last longer.

- Smoother Ride: Reduces vibrations and bumps.

- Enhanced Safety: More reliable steering and braking.

Common Issues With Stock Control Arms

Stock control arms often face several issues:

- Wear and Tear: Stock arms may not withstand heavy use.

- Poor Handling: Reduced performance on challenging roads.

- Rust and Corrosion: Stock materials may corrode over time.

- Vibration Issues: Stock arms might not absorb shocks well.

Upgrading your lower control arms can address these problems. This ensures a better driving experience for your F150.

Choosing The Right Lower Control Arm

Upgrading your F150’s lower control arm can enhance performance. A good upgrade ensures better handling and stability. But choosing the right one can be overwhelming. Let’s dive into the details to help you make an informed decision.

Material Options

When selecting a lower control arm, material choice is crucial. Each material has its own benefits and drawbacks. Here are the common options:

- Steel: Strong and durable, ideal for heavy-duty use. Steel is resistant to impacts but can be heavy.

- Aluminum: Lightweight and resistant to corrosion. Aluminum offers better fuel efficiency but might be less durable under extreme conditions.

- Forged Iron: High strength and excellent durability. Forged iron is great for off-road adventures but can be more expensive.

Brand Comparisons

Choosing a reputable brand ensures quality and performance. Here are some popular brands to consider:

| Brand | Features | Price Range |

|---|---|---|

| Moog | Known for durability and precision engineering. Often includes problem solver technology. | $$ |

| Mevotech | Offers reinforced designs and great warranty options. Ideal for heavy-duty use. | $$ |

| ACDelco | OEM quality, great for daily driving. Known for reliability and affordability. | $ |

| Dorman | Affordable options with decent quality. Great for budget-conscious upgrades. | $ |

Choosing the right brand depends on your needs and budget. Do you need heavy-duty performance? Or are you looking for an affordable upgrade?

Tools And Materials Needed

Upgrading the lower control arm of your F150 is a crucial task. It improves handling, stability, and longevity of your vehicle. Before you start, ensure you have all the necessary tools and materials. This section will guide you through what you need for a successful upgrade.

Essential Tools

- Socket Set: A comprehensive socket set is necessary. It helps to remove and install bolts.

- Wrench Set: Both standard and metric wrenches are required. They are essential for loosening and tightening nuts and bolts.

- Torque Wrench: This tool ensures bolts are tightened to the correct specifications.

- Jack and Jack Stands: These provide stability and safety while working under the vehicle.

- Ball Joint Separator: This tool is critical for separating the ball joint from the control arm.

- Pry Bar: A prying tool helps in manipulating the control arm into place.

Additional Supplies

- Replacement Lower Control Arm: Ensure it fits your F150 model year.

- Grease: Lubricates joints and other moving parts.

- New Bolts and Nuts: Always replace old hardware with new to ensure safety.

- Anti-Seize Compound: Prevents bolts from sticking or seizing.

- Thread Locker: Keeps bolts from vibrating loose over time.

Preparation Steps

Upgrading the lower control arm of your F150 requires careful preparation. This ensures a smooth and safe installation process. Follow these steps to get ready for the upgrade.

Safety Precautions

Safety is your top priority. Wear protective gloves and safety glasses. Have a fire extinguisher nearby. Ensure your workspace is well-ventilated and free of flammable materials. Double-check that all your tools are in good condition. Keep a first aid kit handy. Make sure your vehicle is on a flat, stable surface.

Vehicle Setup

Start by parking your F150 on a level area. Engage the parking brake. Use wheel chocks to prevent the vehicle from moving. Jack up the front of the truck. Secure it with jack stands placed under the frame. Never rely solely on a jack for support.

Remove the front wheels to access the lower control arms. Keep all lug nuts in a safe place. Check the control arm and surrounding components for any visible damage. This ensures a smoother installation process later.

Removal Of Old Lower Control Arm

Removing the old lower control arm from your F150 is a crucial step in the upgrade process. A proper removal ensures a smooth installation of the new part. The process involves a few key steps. Let’s break it down into manageable parts.

Loosening The Bolts

Start by loosening the bolts that secure the lower control arm. Use a wrench or a socket set. Ensure the vehicle is properly lifted and secure on jack stands. This step is critical for safety.

Here’s a quick guide:

- Locate the bolts on the control arm.

- Use a penetrating oil to loosen any rusted bolts.

- Turn the wrench counterclockwise to loosen the bolts.

Pro Tip: Keep track of each bolt. You may need them later.

Detaching The Control Arm

After loosening the bolts, the next step is detaching the control arm. This part requires some careful handling.

- Remove the bolts completely.

- Gently pry the control arm loose from its mount.

- Support the arm as you remove it to avoid damage.

Important: Be cautious of any connected components. Disconnect them before fully removing the arm.

With the old control arm removed, you are now ready to install the new one. Follow the instructions for your specific F150 model. This ensures a proper fit and function.

Credit: khcoap.com

Installing The New Lower Control Arm

Upgrading the lower control arm on your F150 can improve handling and stability. Let’s dive into the process of installing the new lower control arm. We’ll break it down into easy-to-follow steps.

Positioning The New Arm

To begin, align the new lower control arm with the mounting points. Ensure it fits snugly into the designated location. This step is crucial for proper installation.

Check that the control arm is positioned correctly. The ball joint should align with the wheel hub. Double-check all angles to confirm a perfect fit.

Securing Bolts And Nuts

Next, start securing the bolts and nuts. Use a torque wrench to tighten the bolts to the manufacturer’s specifications. Ensure the bolts are tightened in a cross pattern.

- Tighten the first bolt

- Move to the opposite bolt

- Repeat until all bolts are secure

Finally, recheck each bolt to ensure they are all properly tightened. This step ensures your safety and the longevity of the new control arm.

By following these steps, you ensure a smooth installation of your new lower control arm.

Post-installation Checks

After upgrading the F150 Lower Control Arm, it’s crucial to perform some post-installation checks. These checks ensure your vehicle operates safely and efficiently. Let’s look at the essential steps involved.

Alignment Check

Once the new lower control arm is installed, you need to check the alignment. Proper alignment ensures the tires wear evenly and the vehicle handles well.

Follow these steps for an alignment check:

- Park your F150 on a level surface.

- Use an alignment tool or take your vehicle to a professional.

- Check the camber, caster, and toe angles.

- Adjust as necessary to meet the manufacturer’s specifications.

If the alignment is off, it can lead to uneven tire wear and poor handling. Ensure everything is in order before hitting the road.

Test Drive

Conducting a test drive is another critical step. It helps in verifying the installation and alignment.

Here’s what to observe during the test drive:

- Drive at various speeds to check for vibrations.

- Make turns to test the steering response.

- Listen for any unusual noises.

- Feel for any pulling to one side.

Pay attention to how the vehicle handles and responds. If you notice any issues, recheck the installation and alignment. Your goal is to ensure that your F150 performs optimally after the upgrade.

Credit: www.americantrucks.com

Maintenance Tips

Upgrading your F150’s lower control arm is a smart move. But, like any vehicle upgrade, it needs proper care. Regular maintenance ensures your new control arm lasts long and performs well. Here are some essential maintenance tips.

Regular Inspections

Inspect your F150’s lower control arm regularly. Look for any signs of wear or damage. Check the bushings and ball joints for cracks or tears. Ensure all bolts and fasteners are tight. Loose parts can lead to bigger issues. A quick visual check can save you time and money.

Lubrication Tips

Lubrication is key for smooth operation. Use the right grease for your control arm. Apply it to all moving parts. Regularly check and refill grease as needed. Proper lubrication reduces friction and wear. It keeps your control arm functioning well.

Credit: www.ebay.com

Frequently Asked Questions

What Is A Lower Control Arm In An F150?

The lower control arm connects the suspension to the vehicle’s frame, aiding in stability and handling.

Why Upgrade The F150 Lower Control Arm?

Upgrading improves handling, ride comfort, and longevity. It ensures better performance, especially in off-road conditions.

How To Know If My F150 Needs A Lower Control Arm Upgrade?

Look for signs like uneven tire wear, poor handling, or strange noises from the suspension.

Can I Install A Lower Control Arm Upgrade Myself?

Yes, if you have basic mechanical skills and tools. Otherwise, professional help is recommended.

What Are The Benefits Of A New Lower Control Arm?

Enhanced stability, smoother ride, and improved tire life. Helps in better handling and overall vehicle performance.

How Long Does A Lower Control Arm Upgrade Take?

Typically, it takes a few hours. Time may vary based on skill level and tools available.

Conclusion

Upgrading your F150’s lower control arm offers many benefits. Improved handling. Better stability. Enhanced driving experience. The upgrade is straightforward and worth the effort. It ensures a smoother ride. Your truck will perform better on various terrains. Safety is also enhanced.

You’ll notice the difference immediately. Investing in a quality lower control arm is wise. Your F150 deserves the best care and parts. Enjoy the improvements and drive confidently.

- Ford F150 Shaking When Idling - December 23, 2024

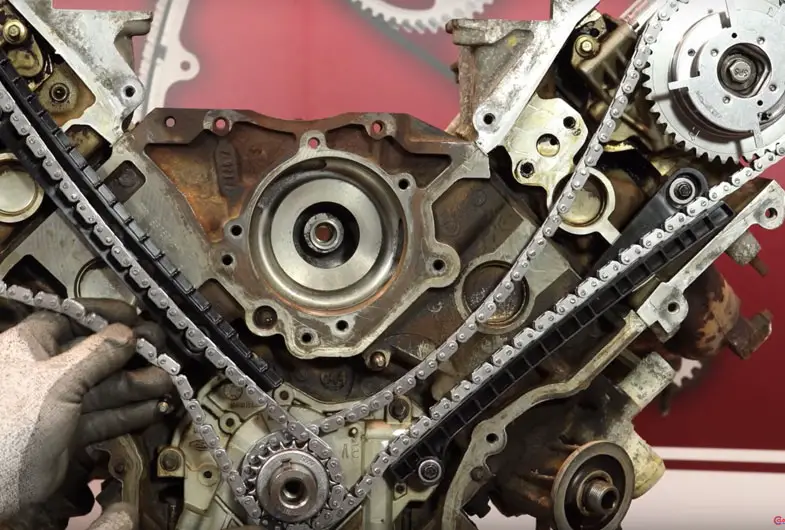

- Ford F150 Timing Chain Replacement - December 23, 2024

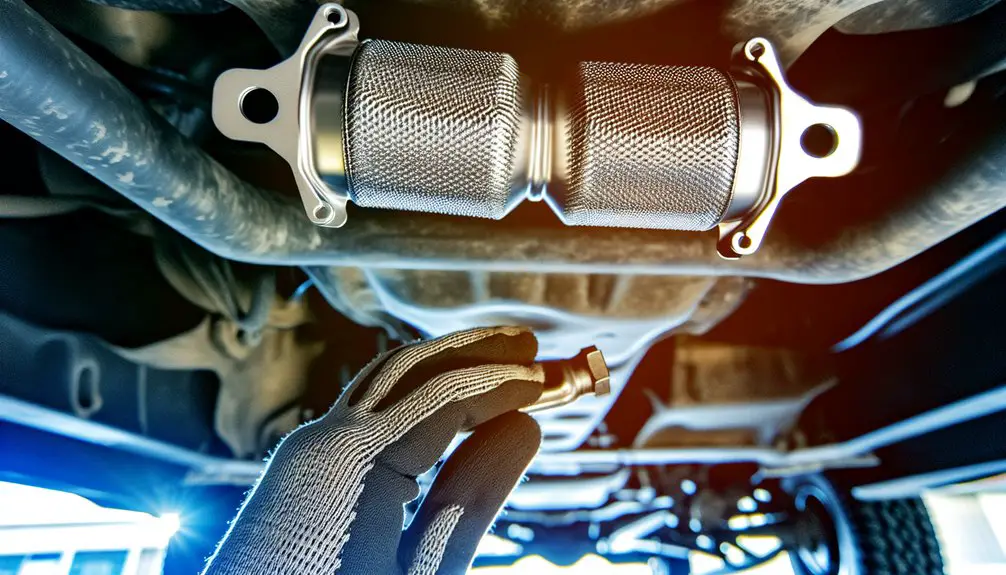

- How Many Catalytic Converters Are In A Ford F150 - December 23, 2024